Newly Developed Fully Automatic Expander DFX2400 which Supports Φ300 mm Wafers and Improves Separation Performance of Small Die Devices

Disco Corporation (Head Office: Ota-ku; President Kazuma Sekiya) has developed DFX2400, a fully automatic expander compatible with Φ300 mm wafers. The DFX2400 will be displayed for the first time at SEMICON Japan 2017 (December 13-15, Tokyo Big Sight).

Development Background

The size of semiconductor chips installed in mobile devices such as smartphones is becoming more

miniaturized. As the demand for sensors for IoT increases, it is expected that the production of small

chip devices will also increase. Stealth dicing (SD) using lasers is an effective form of dicing for this

application. After SD, the dicing tape is expanded resulting in chip division. However, in the subsequent

die bonding step it is necessary to retain the kerf width.

Meanwhile, display driver IC chips installed in LCD and OLED devices have a large aspect ratio, and the

number of division lines varies greatly. Thus, the kerf width in the short side direction could not be

maintained sufficiently using conventional methods, resulting in concerns regarding poor pickup during die

bonding.

Features of the DFX2400

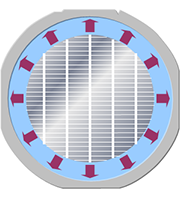

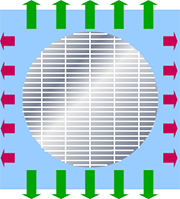

Employs a two-way (XY) expansion method.

- Prior to mounting to the tape frame, the dicing tape is expanded in the X and Y directions separately.

- Expansion control is possible based on the chip size and shape, and is especially effective for long chips.

- Expansion control is also possible when the elongation ratio differs due to the width direction and roll direction of the dicing tape.

- After expansion, heat shrinking* is not necessary, as dicing tape without sag is attached to the tape frame

- Equipment size: W1,560 x D3,833 x H1,800 mm

* The process of removing sag from the dicing tape by shrinking the tape through the application of heat.

Uniform expansion

↓

Irregular chip gap

Large chip expansion in the short side direction.

Small chip expansion in the long side direction.

↓

Uniform chip gap

Future Schedule

| December 2017 | DFX2400 will be displayed at SEMICON Japan 2017 |

|---|---|

| Summer 2018 | Start of sales. |

Contact

Please feel free to contact us with any questions or inquiries.