Merits of Ultrasonic Wave Processing 3

Application processing examples

As a replacement of silicon, SiC (silicon carbide) is attracting attention these days as a material for the next-generation power devices to be used in an inverter module for hybrid automobiles or a converter for a solar power generation system. SiC provides better performance in power consumption, heat resistance, and operation speed compared with silicon, so that it is expected to further reduce the size and weight of devices.

Process Example

When processing an SiC workpiece using a conventional electroformed blade, the blade tends to be glazed

because this material is very hard. Such blade condition may cause chipping or cracking of the wafer or

blade breakage.

Use of ultrasonic waves in dicing lowers cutting resistance, which not only realizes stable processing of

this hard-to-process material but also is effective to prevent blade glazing.

-

Photo 1:Surface processed by ultrasonic waves

-

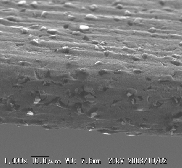

Photo 2:Blade condition after processing

(SEM image after processing 104 lines)

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details