Thickness control by using NCG

Application processing examples

NCG is The Non Contact Gauge.

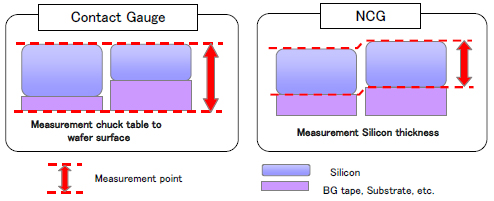

DISCO's Fully Automatic Grinder and Grinder/Polisher usually measure wafer thickness in grinding process and control wafer thickness by contact gauge. NCG measure wafer thickness without contact, and has advantage below.

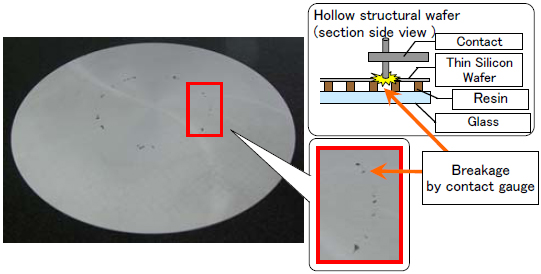

- Avoidance wafer breakage risk by the thickness measurement

NCG avoid the risk of breaking wafer which is weak in load, for example the cavity configuration or a wafer ultrathinning. In the case of grinding such wafers, measuring thickness by the contact gauge itself makes risk of braking by the contact gauge. - Good evaluation of thickness variation between wafers

Because NCG measure only the Silicon thickness, it is possible to decrease Silicon thickness variation, caused by the tape differences or the thickness variation of a hard substrate.

Measurement in grinding process (Height gauge and NCG)

Advantage.1: Wafer break risk reduction

Advantage.2: Good evaluation of thickness variation between wafers

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details