DISCO Corporate History

- 1937-1955Founding – Expansion to Tokyo

- 1956-1974Specialization in ultra-thin blades and venturing into equipment development

- 1975-1984Manufacturing of precision machinery

- 1985-1995Becoming the global standard

- 1996-2003Present Advances in management

- 2004-2011Another new step forward in Omori

- 2012-2015Embodying a new vision of the future

- 2016-Aiming for increase in value-exchangeability

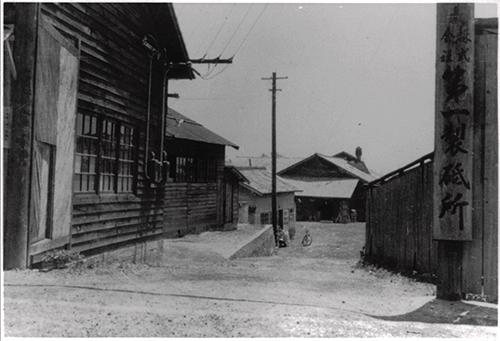

- Mitsuo Sekiya established Dai-Ichi Seitosho Company, Ltd. in Aga-machi, Kure City, Hiroshima Prefecture.

- Production and sales of vitrified grinding wheels begun.

- Dai-Ichi Seitosho Co., Ltd. reorganized as a limited liability company; head office moved to the Kanda district of Tokyo.

- Inanemoto Seitosho Co., Ltd. of Shinagawa Ward, Tokyo, acquired to serve as Tokyo manufacturing facility; head office moved to this location.

- Aga Plant partially rebuilt; production of resinoid cutting wheels begun.

- Head office and Tokyo plant damaged in World War II bombing.

- Plant temporarily closed at end of World War II.

- Aga Plant in Kure City resumes production.

- Head office relocated to Shibatamachi in Minato Ward, Tokyo.

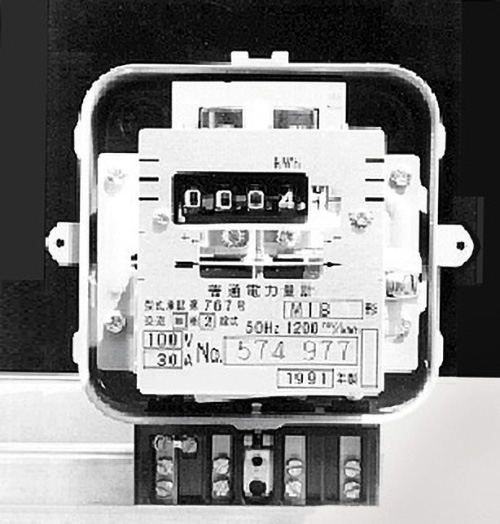

- Abrasive wheel developed to process key part of electricity meters; 100% market share attained.

- Head office relocated to Shiba5-chome in Minato Ward, Tokyo.

Kure City in Hiroshima Prefecture had long been known as a shipbuilding city when, in 1937, DISCO Corporation was founded in its Aga-machi locality as Dai-Ichi Seitosho.

At the time, Kure was home to the Kure Naval Arsenal, which is known for having built the battleship Yamato, and was hailed as Japan’s “high-tech mecca” with its flourishing grinding industry. However, as many excellent companies in the same industry were already established in the area, those companies established later, including Dai-Ichi Seitosho, were unable to complete on a quality level for military orders. Instead, Dai-Ichi reluctantly moved its head office to Tokyo to focus on building business within the civilian sector.

As Japan recovered from the war, Dai-Ichi received an interesting request from an electric meter manufacturer. They needed to grind and polish a C-shaped magnet for use in electricity meters that measure the electricity consumption in individual homes and wanted Dai-Ichi to to produce blades that could grind it. Dai-Ichi gathered a crew of engineers and worked on making thinner blades. They succeeded in developing a thin, high-precision blade (1.2 millimeters thick)—at the time a revolutionary advance in abrasives technology.

Inspired by this success, Dai-Ichi began to take a deep interest in cutting, and in particular accuracy in cutting.

Without the relocation of the head office and the shift in focus to production of thin blades, DISCO as it is today may not have existed.

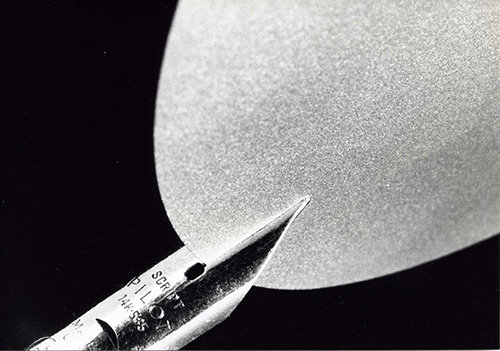

- Japan's first ultra-thin resinoid abrasive wheel developed (thickness 0.13 - 0.14 mm, diameter 100 mm); used to slit fountain pen nibs; mass production begun.

- New plant constructed in Hiro-machi, Kure City (current Kure Plant); cutting wheel division of Aga Plant relocated to this new facility.

- Company reorganized as a joint-stock corporation.

- Ultra-thin (thickness 40 µm) resinoid cutting wheel, MICRON-CUT, developed.

- DISCO ABRASIVE SYSTEMS, INC. established in US.

- DAS/DAD slicing machines developed and released.

DISCO's abrasive wheels continued to grow thinner. In 1968, DISCO introduced MICRON-CUT, a cut-off wheel just 40 micrometers thick. MICRON-CUT won the New Product Award, conferred by leading industrial newspaper Nikkan Kogyo Shimbun, as one of the ten most significant new products of 1968.

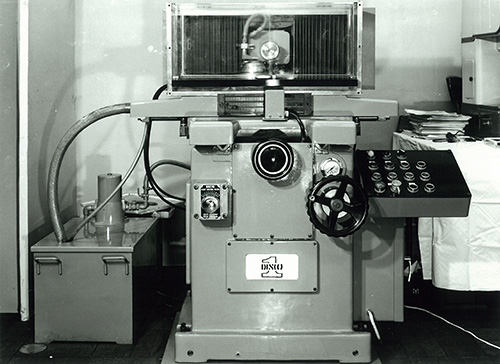

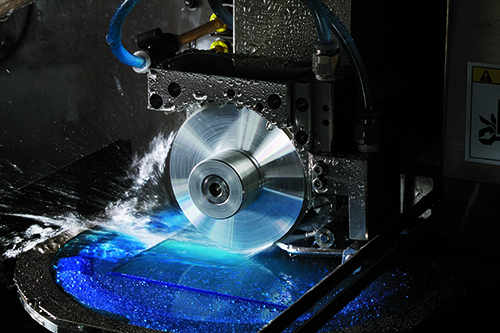

There was still one barrier that stood in the way of even greater success. When a problem was encountered in processing, the equipment manufacturers would usually blame the DISCO abrasive wheel. This was because no equipment existed yet that could truly take advantage of DISCO’s high-precision blades. Even when DISCO commissioned custom-specification equipment from equipment manufacturers, it was unable to handle DISCO’s blades. Thus, DISCO decided that it would have to take on the challenge of producing the equipment itself. DISCO’s stance of focusing on applications (usage technologies), which continues to this day, was the push that led to this first step toward equipment development.

In addition, as its technology developed both in variety and sophistication, DISCO grew into a global company. In 1969, even before the term "Silicon Valley" was coined, DISCO established there its first overseas subsidiary.

In 1974, the University of Tokyo requested that DISCO perform cutting in preparation for analysis of a moon rock that had been brought back to Earth by Apollo 11. This honor was representative of the acclaim that DISCO’s precision dicing technology had obtained even outside its industry.

- Automatic Scriber/Dicing Saw DAD-2H developed and acclaimed a hit when exhibited at SEMICON West.

- Company name changed to DISCO ABRASIVE SYSTEMS, LTD.

- NBC-Z blade developed.

- World's first fully automatic dicing saw DFD-2H/S, developed.

- Received the 1979 Grand Prix at the Good Company Award from the Medium and Small Business Reserch Institue.

- New rotary surface grinder DFG-83H/6, developed.

- Market dominated, with 1,000 DISCO dicing saws in operation at 140 companies in Japan and 140 companies in 28 countries overseas. DISCO awarded Certificate of Appreciation by Texas Instruments for excellence of equipment and technical service.

- NBC-ZH hub blade developed.

- Precision machine maintenance subsidiary DISCO GIKEN (now DISCO ENGINEERING SERVICE) established.

- Sales of TURBOCUT dry diamond cut-off wheels.

- New head office building built in Ota Ward, Tokyo; registered address transferred to this location.

- Kenichi Sekiya was appointed Executive Vice President.

- Large-diameter diamond cut-off wheels for cutting road surfaces begun.

Seven years after the launch of MICRON-CUT, a DISCO R&D team, under the leadership and guidance of Shinji Sekiya (Executive Director at the time), developed DAD-2H, the precursor to the modern-day dicing saw. SEMICON West was scheduled to be held around the same time in Silicon Valley, which meant this was to be DAD-2H’s debut. Since wheel breakage and stoppage frequently occurred during cutting at that time, the team worked with the strong conviction that “DAD-2H should not stop even once during the show”. As a result, the equipment was able to be kept running continuously throughout the show and quickly gained a reputation for its “unstoppability” in comparison to its competitors.

Since DISCO had transformed itself from a small abrasives shop to a leading manufacturer of precision processing tools and equipment and because the character of the company had changed, in 1977, Dai-Ichi Seitosho Co., Ltd. took the D, I, S, and CO in its name and became DISCO.

- Mitsuo Sekiya retired from the position of representative director, President.

Kenichi Sekiya and Shinji Sekiya, who had been working in close partnership, continued as partners in management were appointed representative directors.

Kenichi was appointed as President, concentrating on overall Administration, and Shinji was appointed as Executive Vice President, concentrating on R&D and Marketing.

- DFD-3D/8 dual-spindle dicing saw developed.

- Fully Automatic Surface Grinder DFG-82IF/8 developed.

- Company name changed to DISCO Corporation.

- DISCO registered with the Japan Securities Dealers Association for trading in the over-the-counter market.

- Site of over 100,000 square meters obtained to build Kuwabata Plant.

- DAD320 and DAD500 Series automatic dicing saws developed.

DAD320 - DFD620 and DFD640 fully automatic dicing saws developed.

- DFD650 dual-spindle dicing saw developed.

- ISO 9002 (quality management) certification acquired for precision diamond division.

- CE mark certification received from TUV (recognized testing lab of the EC) for machines bound for Europe.

- ISO 9001 (quality management) certification acquired for PS operating division.

In 1992, DISCO initiated a special new project. The goal was to completely revamp major equipment models in time for the SEMICON Japan trade show to be held one year later. Fifteen members averaging 25 years of age participated.

A section head at a large device maker, stationed at a plant in Kyushu, had originally come to DISCO with a challenge: "We want to put the equipment for each process together, in one big U-shaped production line, so that a single person can operate them all at once. So we need smaller, cheaper manual dicing saws. If you can do this, we’ll take 200 units”. With this challenge, a project was launched to implement a model change, including the development of a manual dicing saw, which previously had not been planned.

The project members worked hard day and night. A year after the launch of the project and after having made some remarkable changes to the equipment, they were able to display a total of 10 units at SEMICON Japan—fully automatic dicing saws DFD620 and DFD640, semi-automatic grinder DAG110, and semi-automatic dicing saw DAD320.

The project was complete, and the section head at the aforementioned device maker was promptly contacted. Unfortunately, he had been transferred to Malaysia and, despite his continued enthusiasm, could only issue an order for 10 units. But it didn't matter. Although the plan had not gone as expected, the new, smaller equipment was an immediate hit around the world.

- DISCO Values was established and shared within the company.

- Hitoshi Mizorogi was appointed as Executive Vice President.

- ISO 14001 (environmental management) certification received for Hiroshima Works.

- 300 mm-compatible dicing saws and grinders developed.

- DISCO shares listed on First Section of Tokyo Stock Exchange.

- Shinji Sekiya retired from the position of representative director and Vice Chairman.

- Nagatani Plant built in Kure City, Hiroshima Prefecture.

- New series dicing saws, DFD6350 and DFD6360, and new series grinder, DFG8540, developed.

- Hitoshi Mizorogi was appointed as President.

- Kenichi Sekiya was appointed as Chairman of Semiconductor Equipment and Materials International (SEMI).

- Dry polishing process developed; world's first dry polisher, DFDP8140, and dry polishing wheels released.

- New grinding wheel series, GF01, developed.

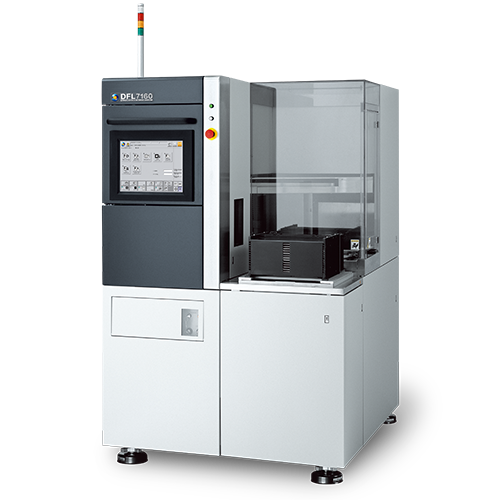

- 300 mm-compatible Fully Automatic Laser Saw DFL7160 developed.

- 8"-compatible Fully Automatic Dicing Saw DFD6240 developed.

- Fully Automatic Grinder/Polisher DGP8760 and Fully Automatic Multi-Mounter DFM2700 (both machines 300 mm-compatible and designed for in-line configuration with each other) developed.

DISCO Values clearly defines the values shared as a company, detailing the approach with which and the direction in which corporate activities should be carried out.

DISCO's increasing size and complexity was the main reason for the introduction of the system. When a company is small, communication is fluid and most employees know each other. Further, employees tend to be generalists, understanding the better part of what goes on inside the firm. In terms of values as well, they understand the kind of actions or initiatives likely to be supported by management, and ethical principles tend to be shared and agreed upon.

As a company grows beyond a certain point, however, the number of employees who know each other decreases. As people's jobs become more specialized, the company as a whole becomes more difficult to comprehend, and employees begin to lose interest in the work of those around them. When this happens, it becomes more and more difficult to share vision and values. This is one of what can be called “big-company diseases,” and it “big-company disease” had begun to show at DISCO. In response to this situation and in order to regain the shared values it had possessed when it was smaller, in 1995, DISCO launched Future Project Alpha, aimed at top management. For over two years, project members had thoroughly discussed DISCO’s purpose, and in December 1997, DISCO introduced DISCO Values to employees.

However, there is no meaning in a system simply being announced. Thus, DISCO Values undergoes continual review and revision to remain consistent with changes in the managerial environment and society, and has come to be shared by all employees while serving as a guide in every activity that DISCO undertakes.

- OHSAS 18001 certification received for Hiroshima Works.

- Head office and R&D center was relocated to 13-11 Omori-kita 2-chome, Ota-ku, Tokyo.

- New DISCO company logo was introduced.

- 6"-compatible automatic dicing saw DAD3220/3230/3430 and 8"-compatible fully automatic dicing saw DFD6450 developed.

DAD3230 - New dicing blade series ZH05 and Z05, new grinding wheel Poligrind and a new grinding wheel bond BT100 for the GF01 Series developed.

- Consolidation with the maintenance and service subsidiary DISCO ENGINEERING SERVICE, LTD.,

- Developed dicing application using ultrasonic wave.

- Developed a backgrinding processing method called "TAIKO".

- Kenichi Sekiya retired from the position of representative director and Chairman. And He was appointed as Honorary Chairman.

- Expanded ISO14001 certification to all factories in Japan.

- Shinano Denki became a subsidiary and changed name to Daiichi Components.

- Laser processing technology to improve production of high-intensity LED developed.

- Kenichi Sekiya appointed as Director Emeritus of SEMI.

- Developed the DFL7340/7360 laser saws based on a business alliance with Hamamatsu Photonics

- Developed the DFD6362 dicing saw for 300 mm wafer processing.

- Developed the DP08 Series dry polishing wheel.

- Developed the DGP8761 grinder/polisher for 300 mm wafer processing and the DFM2800 multi-wafer mounter.

- Completed construction of building at Head Office R&D Center (B-Building)

- Obtained certification for Business Continuity Management System Standard (BS25999-2: 2007).

- Developed the DWR1720 deionized water recycling unit, which produces zero wastewater, for use with dicing saws.

- Developed the DDS2300 fully automatic die separator.

- Developed the 10 µm thick ZHZZ hub blade, which is the thinnest hub blade in the industry.

- Hitoshi Mizorogi was appointed as Chairman and CEO, and Kazuma Sekiya was appointed as President and COO.

- Introducing the DAD3650, the world's smallest dual-spindle automatic dicing saw.

- Introducing the DFL7161, Fully Automatic Laser Saw for 300 mm Wafers with Enhanced Basic Performance.

- Completion of a new building at the Kuwabata plant.

- Completion of a new building at the Chino plant.

- Established a service office in Vietnam.

- Developed the DWR1721 Deionized Water Recycling Unit with drain water pumping and communication functions with the dicing saw.

- Developed the ultra high precision DFS8960 surface planer which supports 300 mm wafers.

- Developed the DFG8830, a grinder with a 4-axis and 5-chuck table configuration for hard and brittle materials such as sapphire and SiC.

- Developed the DAD3360 Automatic Dicing Saw with extended support for 300 mm wafers.

In November 2004, DISCO relocated from Higashi-Kojiya(Tokyo, Ota-ku), which had been its base for nearly twenty years, to the new head office and R&D center in Omori-Kita(Tokyo, Ota-ku).

When the head office moved to Higashi-Kojiya from Shinagawa in 1984, the number of employees working there was about two hundred. After the move, the number of employees increased with the growth of DISCO, and twenty years later in 2004 the number of employees working at the head office was approaching one thousand. As a result of repeated measures to increase the facilities for employees, such as rebuilding aged buildings and constructing new buildings, the head office facilities in 2004 were dispersed over seven locations, with six buildings in Higashi-Kojiya and the training center in Higashi-Shinagawa several kilometers away. Since sometimes the trial manufacture site, application lab or one's desk was located in different buildings, on rainy days engineers where often seen walking quickly between two buildings carrying a tool box in one hand and an umbrella in the other.

After the head office moved to Omori-Kita in 2004, all of DISCO's core facilities, such as administration, R&D, application lab and service departments, were in the same building. This has enabled DISCO to provide better service and solutions more efficiently to the customer.

- Completed construction of building at Kure Plant (C-Building).

- Established a service office in the Philippines.

- Became the first Japanese company to earn certification under the ISO 22301:2012 Business Continuity Management System Standard.

- Developed the DFL7361, stealth dicing laser saw, for ø300 mm wafers with support for various processes.

- Transfer of all owned shares in consolidated subsidiary company TECNISCO LTD..

- Developed the DAD323, the world’s smallest footprint automatic dicing saw with expanded functionality.

- Developed DPEG-MZ, a gettering DP wheel to improve die strength.

- Developed ZH14 series hub blades for stable processing under high load conditions.

- Introducing the DWR1722, a DI water recycling unit with high customizability, and StayClean-R, a cutting water additive which can be used in conjunction with the DWR series.

- Completed construction of building at Kuwabata Plant (Zone B, A-Building).

- Implementation of a free-choice work location system.

- Developed the DAD3660, a dual spindle automatic dicing saw with support for workpieces as large as 360 mm x 360 mm.

- Developed a unique laser-lift off optimal for high brightness vertical structured LED manufacturing.

In February 2015, construction was completed on the new building at DISCO's largest manufacturing affiliate, Kuwabata Plant (Kure City, Hiroshima Prefecture). The official name of the new building is "B Zone, A Building, Kuwabata Plant". The building serves as a structure for housing large equipment, and is the same size as A Building. Around the same time, road construction around the plant progressed, allowing the Kuwabata Plant to be seen from places that were previously inaccessable. Seeing the tall mountains and the eight story Kuwabata Plant, far removed from inner Kure City, is truly breathtaking.

In March, one month after the completion of the new building, the "Higashihiroshima, Kure Expressway" was fully opened, connecting the Sanyo Expressway and the Aga region near DISCO's Kure Plant. An interchange for the expressway was also built just next to Kuwabata Plant. The expressway can now be used for the majority of the trip when travelling from Hiroshima Airport to the Kuwabata Plant and Kure Plant. Easier access to the plants for both DISCO employees and for customers visiting the plants from within Japan and from overseas is long-awaited good news for DISCO.

- Held the first “DISCO Presents Discovery Channel Code Contest”.

Developed KABRA®, a new laser slicing technology.

- Developed fully automatic polisher that supports CMP of difficult-to-process materials, including sapphire.

- Developed DFD6310, a panel level packaging compatible dicing saw.

- Received recognition from Health & Productivity Management Outstanding Organizations Recognition Program (White 500).

Received CEATEC Award 2017 for KABRA® process.

- Developed DFD6562, a small-footprint, fully automatic dicing saw that supports Φ300 mm wafers.

- Developed parallel processing transfer system for realizing efficient wafer processing.

- Developed DFL7362, a stealth dicing laser saw that achieves higher throughput.

Developed KABRA!zen®, a full-automatization of KABRA® laser slicing technology.

- Completed construction of new Kyushu Branch building and relocated.

- Began operations at Nagano Works Chino Plant.

- Developed DFG8640, a fully automatic grinder compatible with Φ8-inch wafers, which achieves high-precision processing of difficult-to-grind materials.

- Model change for all four semi-automatic dicing saw models.

- Developed a system for monitoring and control of precision processing equipment using a smartphone or other device.

- Completed construction of building at Kuwabata Plant (Zone C, A-Building).

- Chosen for the Health & Productivity Stock Selection Program for the first time.

- Certified as a “Tokyo Model Company for Promotion of Stranded Commuter Prevention”.

- Became the first company to develop and publish a JSA standard, “Employee Satisfaction Standards JSA-S1001”.

- Relocated USA Office in California.

- Developed DAD3351, DAD3361, and DAD3431. All semi-automatic dicing saw models were remodeled.

- DDS2320, a fully-automatic die separator, was developed.

- Cluster system "MUSUBI" and three compatible equipment models added to product lineup.

- Kuwabata Plant, Hiroshima Works won the 8th "Green Society Contribution Award".

- Received the "Ministerial Award for Regional Revitalization Support Tax System (Corporate Hometown Tax Payment)" from the Cabinet Office.

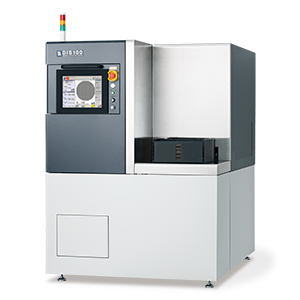

- Developed DIS100, an inspection system.

- Developed fully-automatic grinders DFG8020 and DFG8030.

- Completed construction of Building B at Chino Plant.

- Completed construction of Building A, Zone D at Kuwabata Plant, and completed expansion work for Building A.

- Established the Haneda R&D Center at Higashikojiya, Ota-Ku, Tokyo.

- Transitioned the listing of stock market shares from the First Section of Tokyo Stock Exchange to "Prime Market" a new market category.

- Transitioned the corporate governance structure to a Company with Three Committees.